How technology is shaping future of construction and easing burden on manual labourers

Pullers and other machines are now employed to transport stones, cement, and other materials to higher floors, showcasing the integration of technology into modern construction practices.

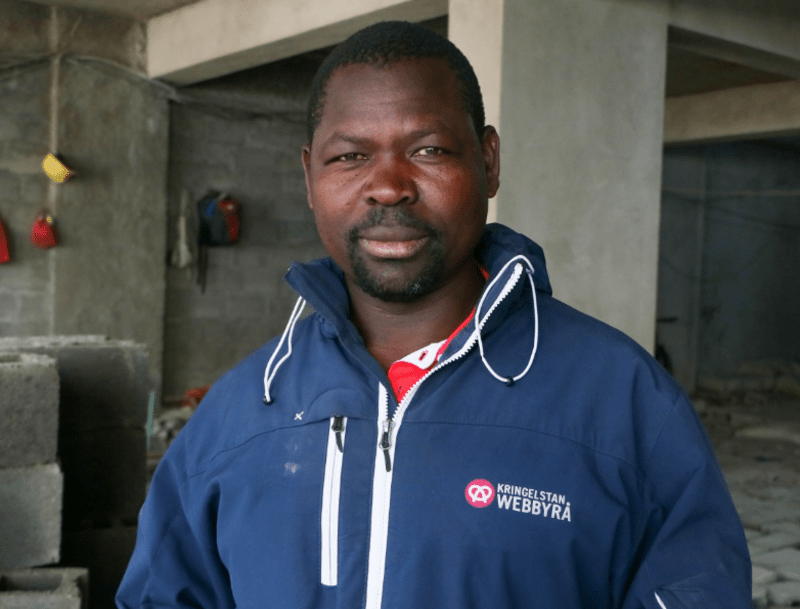

Moses Oguk, now a seasoned foreman with over 15 years in the construction industry, has witnessed significant changes that have transformed the work environment for construction workers.

“When I began my career in construction, it was extremely labour-intensive. We used to carry stones, sand, cement, and other materials on our shoulders. It was gruelling work that many people shied away from. The demanding nature of the job often led to injuries such as back pain, cuts from stones, and general exhaustion challenges that labourers had to endure in those days." said Oguk.

More To Read

- How blocked drainage systems, open sewers threaten lives, businesses in Eastleigh

- MP Yusuf Hassan donates food, blankets to victims of three Kamukunji fire incidents

- Nairobi Chief Officer Geoffrey Mosiria leads crackdown on illegal dumping, hawkers in Eastleigh

- Eastleigh mall owners protest return of hawkers, call for county action

- Relief for Eastleigh residents as construction begins on Seventh Street after years of neglect

- From fires to missing children: How Eastleigh’s communal spirit responds to crisis

In the modern day, the landscape of construction has changed dramatically. “Building is much easier now,” Oguk explains.

“Manual labourers no longer have to carry heavy loads manually. Technological advances like pullers and other machinery, have significantly eased the workload.”

Moses Oguk, the foreman in a construction building in Eastleigh California Ward on August 15. (Photo: Justine Ondieki)

Moses Oguk, the foreman in a construction building in Eastleigh California Ward on August 15. (Photo: Justine Ondieki)

In Eastleigh, the construction of high-rise buildings has driven the adoption of advanced technology. Pullers and other machines are now employed to transport stones, cement, and other materials to higher floors, showcasing the integration of technology into modern construction practices.

Oguk notes that many of these machines and technological solutions have been imported from China and tailored to meet the specific needs of construction projects, reflecting a global influence on local industry advancements.

Peter Olewa, a seasoned mason who has been in the construction industry since 1995, continues to find great fulfilment in his work.

“I began my career in construction in 1995, starting with a modest earning of just Sh30. However, within six months of closely observing and working alongside others, I improved my skills and transitioned into the role of a mason,” Olewa recounts.

Construction workers arranging stones at the construction site in Eastleigh on August 15. (Photo: Justine Ondieki)

Construction workers arranging stones at the construction site in Eastleigh on August 15. (Photo: Justine Ondieki)

Olewa's decision to enter the construction field was influenced by limited access to formal education. “At the age of 15, I chose to pursue a career in construction as a way to support my family,” he says.

He acknowledges that advancements in technology have transformed their approach to work. Yet, there are times when they must revert to manual labour due to various challenges. “When we encounter situations where technology is inaccessible, workers often have to carry stones on their shoulders up to the site,” Olewa explains.

To ensure fairness, each worker is assigned a target of 100 stones, allowing them to work at their own pace. “Despite the advancements, we sometimes have to do it manually. It’s tough work, but many endure it to earn their pay of Sh500,” he notes.

Olewa acknowledges that the demanding manual labour they once performed has changed significantly, resulting in fewer injuries today.

Kevin Otieno, a labourer with a decade of experience on construction sites in Eastleigh, shares his perspective on the evolving industry. He recognises that while technological advancements have greatly improved their working conditions and reduced injuries. They have also brought new challenges.

“After working in construction for ten years, I’ve seen how technology has made our jobs easier and safer but it’s frustrating when some foremen don’t understand that we’re still putting in a lot of effort. They see the machines doing much of the work and forget that we’re the ones operating them. We’re often exhausted, but it’s like they don’t see that.”

Construction machines at the site in Eastleigh California ward on August 15. (Photo: Justine Ondieki)

Construction machines at the site in Eastleigh California ward on August 15. (Photo: Justine Ondieki)

Kevin also said due to the technology there is a reduction in the number of jobs available. “With more machines taking over tasks, fewer people are needed on site, which makes finding work tougher,” he explains. “Most of us have to rely on personal connections and referrals to secure jobs because the competition is so intense and opportunities are limited.”

In Eastleigh, manual labourers earn between 400 and 700 shillings a day, depending on the specific site and the type of labour involved. The area remains a hotspot for labourers, who flock to the region daily for job opportunities. This influx is driven by the ongoing demand for construction work, with many workers scouting for potential openings to secure their daily income.

Machines have significantly eased many of the burdensome tasks in construction. For example, tasks such as mixing cement, transporting stones, cement, and bricks, and moving mixed cement and ballast to higher floors have been automated.

Labourers now only need to load these materials onto the machines, which then handle the heavy lifting and delivery to the required floors. This automation has greatly reduced the physical strain on workers by managing the more labour-intensive aspects of their jobs.

President William Ruto recently offered Eastleigh developers unlimited opportunities in the commercial real estate sector by removing the previous height restriction on buildings. This move is expected to attract even more opportunities to the area.

“As the Commander-in-Chief, I am pleased to announce that the previous limit of 12 Storeys for buildings in Eastleigh has been removed. Developers can now construct up to 25 or even 30 storeys. This change will help provide more accommodation options for citizens and foster harmonious communities,” Ruto stated during a speech in Kiamaiko, Mathare, on May 6.

Top Stories Today